Products

Contact

South of Dikouzhang Village, 104 National Road, Botou, Hebei, China

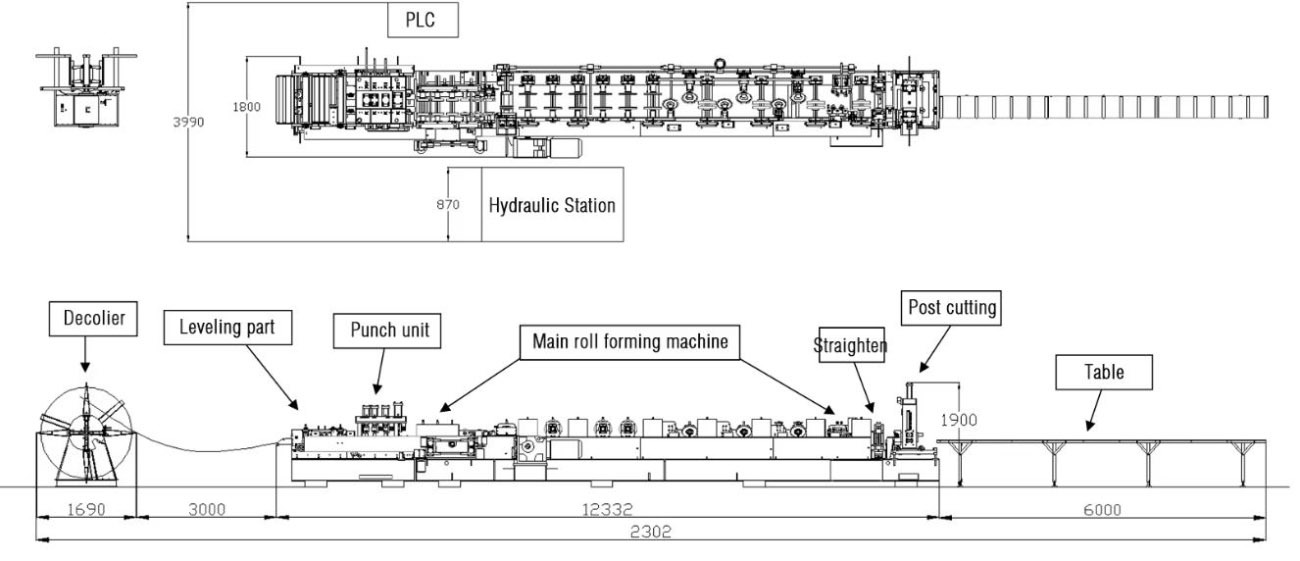

Full Automatic Metal High Speed CZ-Interchange-Purlin-Machine

- 产品描述

-

Product Introduction

CZ purlin forming machine can be designed with Z , that is CZ purlin forming machine, with different sizes of 100-300mm, three sets of punching, and raw material thickness of 1.5-3.0mm, which basically meets the needs of different purlins on the market.or only C purlin machine from 3 inch to 10 inch, or punch holes or what thickness of raw material.

1. Factory Lifetime Service:offer technical support for the entire life of our machines.

2. Customized Profile:can design the profile according to customer request.

3. ONE-YEAR Guarantee Period:we could supply you the replacement parts free of charge for any damaged parts caused by quality problems.

4. Overseas Services Optional:we can send our technicians to install and train the workers in the clients' factories with extra cost.

Products Description

1. Full automatically change size from 100mm to 300mm by PLC control in 1 minute.

2. Easy operating for manual changing C purlin to Z purlin in half hour.

3. Servo motor driving system.

4. Hydraulic pre-ctter+Hydraulic post-cutter.

5. Rolling thickness available from 1.2-3.0mm,working speed:0-30m/min.

Main Technical Data

Size for C Purlin 80-300mm Size for Z Purlin 120-300mm Machine Dimension 11000*1800*1500mm Machine Weight 1ltons Material Thickness 1.2-3.0mm Main Servo Motor Power 30KW Forming Steps 18steps Running Speed 0-30m/min Hydraulic Power 7.5KW Machine Frame Material H-Beam with 30mm thickness Full Automatic Metal High Speed CZ-Interchange-Purlin-Machine 1.Formed Material GI Thickness:1.5-3 mm (standard) 2.Decoiler 3 Tons Hydraulic automatic decoiler 3 Tons Manual decoiler(will give you as free) 3.Main body Roller station As your requirement Diameter of shaft 80 mm solid shaft Material of rollers 45# steel, hard chrome plated on the surface Machine body frame 400 H steel Drive Gear and chains transmission Dimension(L*W*H) 15000*1800*1600(customize) Weight 7.5T 4.Cutter Automatic cr12mov material, no scratches, no deformation 5.Power Motor Power 11KW Hydraulic system power 5.5KW 6.Voltage 380V 50Hz 3Phase As your requirement 7.Control system Electric Box Customized(famous brand) Language English(Support multiple languages) PLC Automatic production of the whole machine. Can set batch, length, quantity, etc. 8.Forming Speed 25 m/min The speed depends on the shape of the tile and the thickness of the material. Product Parameters

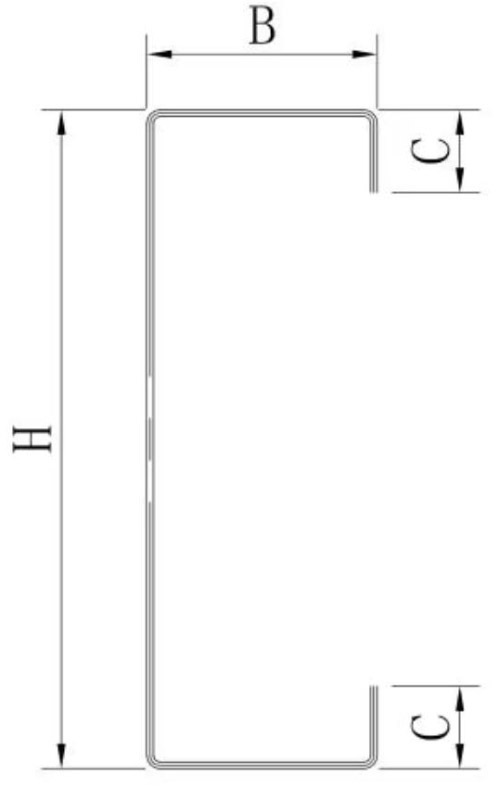

C Purlin Model Section Size H B C C100 100 40 14 C120 120 40 16 C140 140 50 16 C160 160 50 16 C180 180 60 18 C200 200 60 18 C220 220 70 18 C250 250 70 20 C280 280 80 20 C300 300 80 20

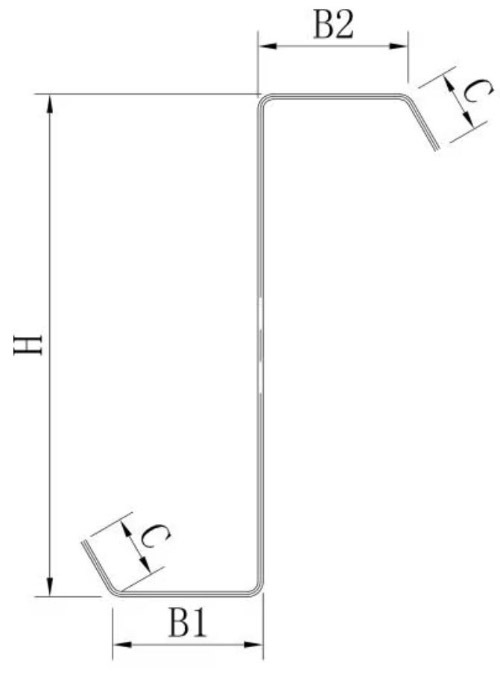

Z Purlin Model Section Size H B1 B2 C Z120 120 55 50 16 Z140 140 55 50 16 Z160 160 67 61 16 Z180 180 67 61 18 Z200 200 67 61 18 Z220 220 78 72 18 Z250 250 78 72 20 Z280 280 78 72 20 Z300 300 78 72 20 Note: the above dimensions are commonly used, and the actual dimensions ((within the size range) can be set at will in actual use.

Punching devices

1.Punching method: Pre punching, allowing punching flange hole/web hole/single and double holes;

2.Puncher material: SKD11;

3.Punching specifications: 14*25mm(available customized);

Hydraulic Cutting devices

1.Cutting mode: pre cutting, two-piece staggered knife, cutting without waste;

2.Cutter material: SKD11;

Production Line

01

MANUAL ARC WELDING IS ONE OF THE MOST BASIC AND COMMONLY USED FRAME WELDING PROCESSES. BY GENERATING HIGH TEMPERATURE AT THE CONTACT POINT BETWEEN THE ARC OF THE WELDING ROD AND THE METAL WORKPIECE, THE TWO METAL WORKPIECES ARE MELTED AND BONDED TOGETHER. MANUAL ARC WELDING HAS THE ADVANTAGES OF HIGH FLEXIBILITY AND SUITABILITY FOR VARIOUS WORKPIECES AND POSITIONS.

02

MECHANICAL PROCESSING INVOLVES EXPENSIVE CNC GRINDERS AND MILLING MACHINES USED TO MANUFACTURE ROLLERS AND SHAFTS. AFTER THE FINISHED PRODUCT, PLEASE HAVE A PROFESSIONAL ENGINEER CHECK IF IT IS QUALIFIED. FROM ONE ROLL TO ONE MACHINE, WE ENSURE QUALITY AT EVERY STEP.

03

ENVIRONMENT-FRIENDLY SPRAYING EQUIPMENT

METAL STEEL PROFILE ROOF TILE COLD ROLL FORMING MACHINE ELECTROSTATIC SPRAYING EQUIPMENT MEETS THE ENVIRONMENTAL PROTECTION REGULATIONS OF THE CHINESE GOVERNMENT AND GUARANTEES THE DELIVERY TIME OF THE MACHINE.METAL STEEL PROFILE ROOF TILE COLD ROLL FORMING MACHINE.

Company Profile

BOTOU XINGHE Roll Forming Machinery Manufacturing Co., Ltd. is the manufacturer specialized in cold roll forming equipment and automatic production line. It covers an area of more than 10000 square meters.The company is the strength of strong technical strength of cold forming equipment and complete sets of automatic production line manufacturers.

Main products are color steel roof/wall roll forming machine, classical glazed tile forming machine, C/Z purlin machine, light gauge ceiling roll forming machine, floor deck forming machine, sandwich panel production line, guardrail roll forming line, container house frame production line, standing seam roofing machine wall maintenance structure color board or insulation board; Environmental protection industry dust anode plate, cathode plate; Transportation industry high-speed guard plate, automobile cold-formed profiles can also provide users with a variety of coil unwinding, leveling, longitudinal shear winding, transverse shear palletizing production lines and various kinds full-automatic cold roll forming equipment.

Qualifications

Customer Photo

Exhibition

Packaging and Transportation

FAQ

★ Q1. WHAT'S YOUR DELIVERY TIME?

A1: DEPENDING ON THE TYPE OF MACHINE, DURATION OF 30 DAYS TO 60 DAYS FROM THE DATE OF ORDER.

★ Q2. DO YOU HAVE AFTER-SALES SUPPORT?

A2: YES, WE ARE HAPPY TO GIVE ADVICE AND WE ALSO HAVE SKILLED TECHNICIANS AVAILABLE ACROSS THE WORLD.WE NEED YOUR MACHINES RUNNING IN ORDER TO KEEP YOUR BUSINESS RUNNING.

★ Q3. DO YOU SELL ONLY STANDARD MACHINES?

A3: NO, MOST OF OUR MACHINES ARE BUILT ACCORDING TO CUSTOMERS SPECIFICATIONS,USING TOP BRAND COMPONENTS.

★ Q4. WHAT WILL YOU DO IF THE MACHINE IS BROKEN?

A4: OUR MACHINE'S WARRANTY PERIOD IS 12MONTHS,IF THE BROKEN PARTS CAN'T REPAIR,WE CAN SEND THE NEW PARTS REPLACE THE BROKEN PARTS FREELY,BUT YOU NEED PAY THE EXPRESS COST YOURSELF.IF IT IS BEYOND THE WARRANTY PERIOD,WE CAN NEGOTIATE TO SOLVE THE PROBLEM,AND WE SUPPLY THE TECHNICAL SUPPORT FOR THE WHOLE LIFE OF THE EQUIPMENT.

★ Q5. CAN YOU BE RESPONSIBLE FOR TRANSPORT?

A5: YES,PLEASE TELL ME THE DESTINATION PORT OR ADDRESS.WE HAVE RICH EXPERIENCE IN TRANSPORTING.

★ Q6. HOW TO VISIT YOUR COMPANY?

A6: 1) FLY TO BEJJING AIRPORT, BY HIGH SPEED TRAIN FROM BEIING NAN TO CANGZHOU XI(1 HOUR).

2) FLY TO SHANGHAI AIRPORT: BY HIGH SPEED TRAIN FROM SHANGHAI HONGOIAO TO CANGZHOU XI(4.5 HOURS), THEN WE CAN PICK UP YOU.

TAG:

Related Products