Products

Contact

South of Dikouzhang Village, 104 National Road, Botou, Hebei, China

Deck Flooring Roll Forming Machine Floor Metal Decking Sheet Tiles Roll Forming Machine Steel Metal Decking Forming machine

- 产品描述

-

Product Introduction

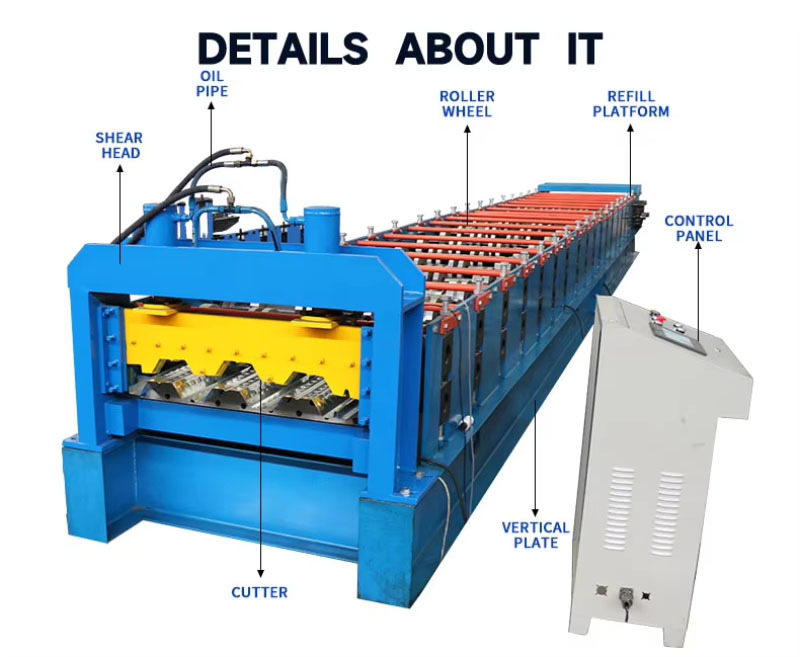

Customized Manufacturer Steel Metal Floor Decking Roll Forming Machine is an outstanding piece of equipment in the construction field. It combines high precision with excellent performance, enabling it to produce top-quality floor decking products efficiently.

This machine is designed to roll form steel sheets into perfect floor decking with ease. With its advanced technology and reliable components, it can operate smoothly and continuously, ensuring a stable production process. Moreover, it allows for easy adjustment and customization, which means you can meet various project requirements.

Whether you are working on a large commercial building or a smaller industrial facility, the Customized Manufacturer Steel Metal Floor Decking Roll Forming Machine and the Composite Floor Deck Machine are your ideal choices to create durable and sturdy floor decking, helping you complete construction projects successfully and enhance the overall quality of the structures.

Product Parameters

1.Formed Material PPGI,GI,AI Thickness:0.7-1.6mm Width:1220mm (as request) 2.Decoiler Hydraulic automatic decoiler Manual decoiler(will give you as free) 3.Main body Roller station 28 rows(As your requirement) Diameter of shaft 90mm solid shaft Material of rollers 45# steel, hard chrome plated on the surface Machine body frame 400 H steel Drive Chain transmission Dimension(L*W*H) 9500*1600*1600(customize) Weight 8T 4.Cutter Automatic cr12mov material, no scratches, no deformation 5.Power Motor Power 30KW Hydraulic system power 5.5KW 6.Voltage 380V 50Hz 3Phase As your requirement 7.Control system Electric Box Customized(famous brand) Language English(Support multiple languages) PLC Automatic production of the whole machine. Can set batch, length, quantity, etc. 18.Forming Speed 15-20m/min The speed is adjustable

Production Line

01

MANUAL ARC WELDING IS ONE OF THE MOST BASIC AND COMMONLY USED FRAME WELDING PROCESSES. BY GENERATING HIGH TEMPERATURE AT THE CONTACT POINT BETWEEN THE ARC OF THE WELDING ROD AND THE METAL WORKPIECE, THE TWO METAL WORKPIECES ARE MELTED AND BONDED TOGETHER. MANUAL ARC WELDING HAS THE ADVANTAGES OF HIGH FLEXIBILITY AND SUITABILITY FOR VARIOUS WORKPIECES AND POSITIONS.

02

MECHANICAL PROCESSING INVOLVES EXPENSIVE CNC GRINDERS AND MILLING MACHINES USED TO MANUFACTURE ROLLERS AND SHAFTS. AFTER THE FINISHED PRODUCT, PLEASE HAVE A PROFESSIONAL ENGINEER CHECK IF IT IS QUALIFIED. FROM ONE ROLL TO ONE MACHINE, WE ENSURE QUALITY AT EVERY STEP.

03

ENVIRONMENT-FRIENDLY SPRAYING EQUIPMENT

METAL STEEL PROFILE ROOF TILE COLD ROLL FORMING MACHINE ELECTROSTATIC SPRAYING EQUIPMENT MEETS THE ENVIRONMENTAL PROTECTION REGULATIONS OF THE CHINESE GOVERNMENT AND GUARANTEES THE DELIVERY TIME OF THE MACHINE.METAL STEEL PROFILE ROOF TILE COLD ROLL FORMING MACHINE.

Company Profile

BOTOU XINGHE Roll Forming Machinery Manufacturing Co., Ltd. is the manufacturer specialized in cold roll forming equipment and automatic production line. It covers an area of more than 10000 square meters.The company is the strength of strong technical strength of cold forming equipment and complete sets of automatic production line manufacturers.

Main products are color steel roof/wall roll forming machine, classical glazed tile forming machine, C/Z purlin machine, light gauge ceiling roll forming machine, floor deck forming machine, sandwich panel production line, guardrail roll forming line, container house frame production line, standing seam roofing machine wall maintenance structure color board or insulation board; Environmental protection industry dust anode plate, cathode plate; Transportation industry high-speed guard plate, automobile cold-formed profiles can also provide users with a variety of coil unwinding, leveling, longitudinal shear winding, transverse shear palletizing production lines and various kinds full-automatic cold roll forming equipment.

Qualifications

Customer Photo

Exhibition

Packaging and Transportation

FAQ

★ Q1. WHAT'S YOUR DELIVERY TIME?

A1: DEPENDING ON THE TYPE OF MACHINE, DURATION OF 30 DAYS TO 60 DAYS FROM THE DATE OF ORDER.

★ Q2. DO YOU HAVE AFTER-SALES SUPPORT?

A2: YES, WE ARE HAPPY TO GIVE ADVICE AND WE ALSO HAVE SKILLED TECHNICIANS AVAILABLE ACROSS THE WORLD.WE NEED YOUR MACHINES RUNNING IN ORDER TO KEEP YOUR BUSINESS RUNNING.

★ Q3. DO YOU SELL ONLY STANDARD MACHINES?

A3: NO, MOST OF OUR MACHINES ARE BUILT ACCORDING TO CUSTOMERS SPECIFICATIONS,USING TOP BRAND COMPONENTS.

★ Q4. WHAT WILL YOU DO IF THE MACHINE IS BROKEN?

A4: OUR MACHINE'S WARRANTY PERIOD IS 12MONTHS,IF THE BROKEN PARTS CAN'T REPAIR,WE CAN SEND THE NEW PARTS REPLACE THE BROKEN PARTS FREELY,BUT YOU NEED PAY THE EXPRESS COST YOURSELF.IF IT IS BEYOND THE WARRANTY PERIOD,WE CAN NEGOTIATE TO SOLVE THE PROBLEM,AND WE SUPPLY THE TECHNICAL SUPPORT FOR THE WHOLE LIFE OF THE EQUIPMENT.

★ Q5. CAN YOU BE RESPONSIBLE FOR TRANSPORT?

A5: YES,PLEASE TELL ME THE DESTINATION PORT OR ADDRESS.WE HAVE RICH EXPERIENCE IN TRANSPORTING.

★ Q6. HOW TO VISIT YOUR COMPANY?

A6: 1) FLY TO BEJJING AIRPORT, BY HIGH SPEED TRAIN FROM BEIING NAN TO CANGZHOU XI(1 HOUR).

2) FLY TO SHANGHAI AIRPORT: BY HIGH SPEED TRAIN FROM SHANGHAI HONGOIAO TO CANGZHOU XI(4.5 HOURS), THEN WE CAN PICK UP YOU.

Related Products